More

約1時間 ago

約1時間 ago

Cookie Mommy ® @wei_ying

commented on

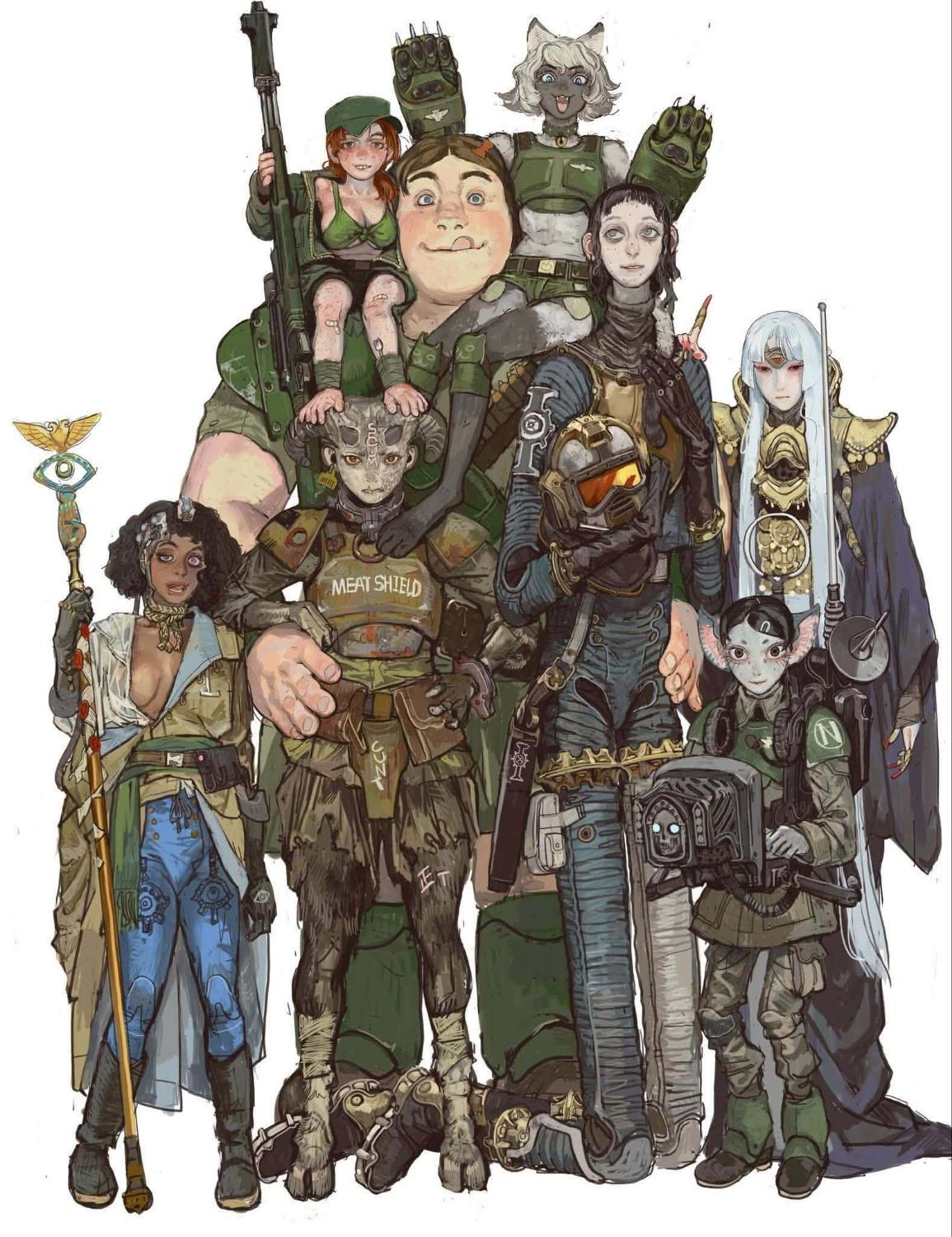

Mommy's Character Creations and Stories

Cookie Mommy ® @wei_ying

More

約2時間 ago

https://youtu.be/wdPXmkQiKiU?si=4HqrMMm1bhmjHNg4

More

約9時間 ago

More

約9時間 ago

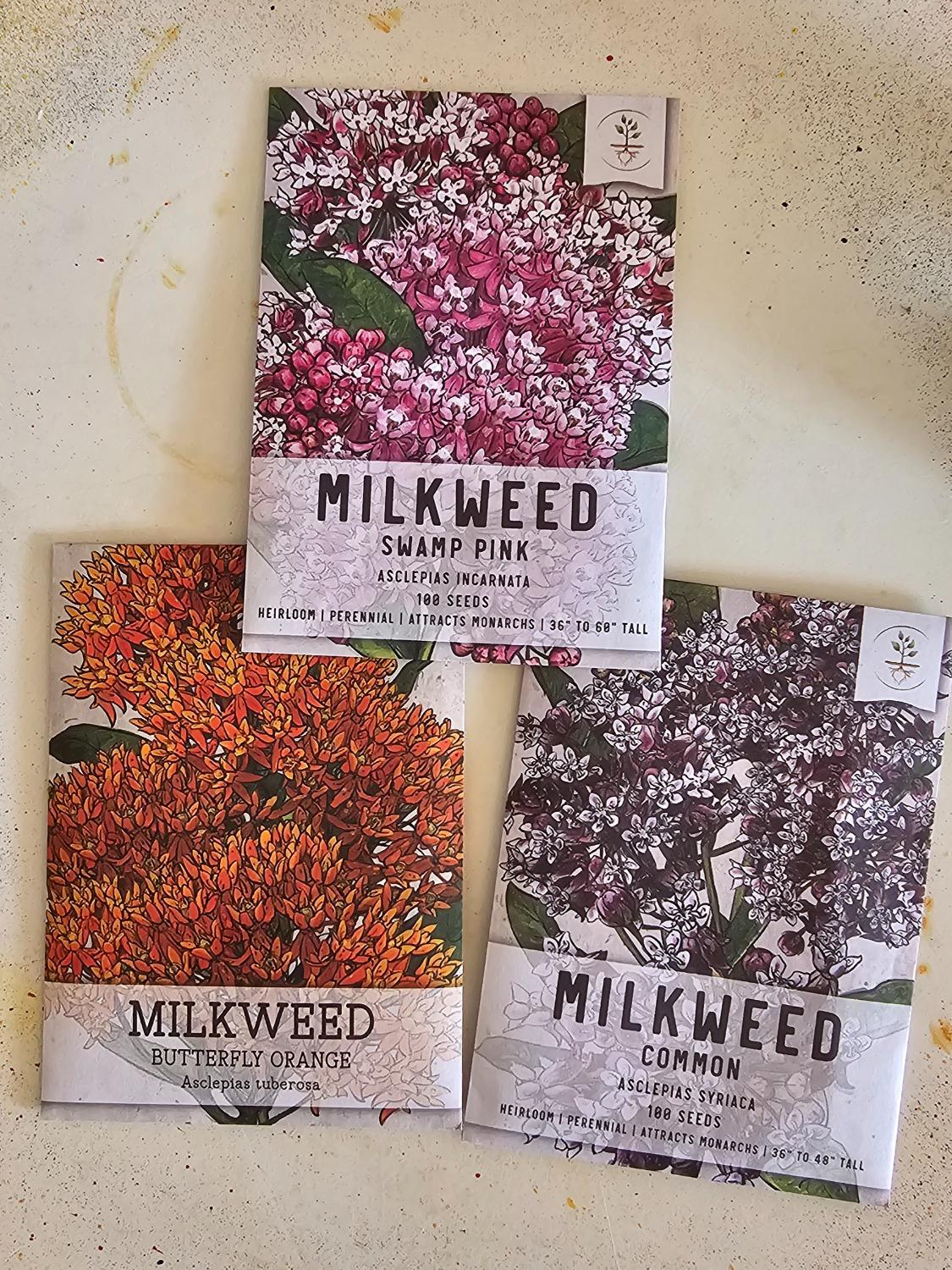

Listening to Spyro the Dragon music while planting new seeds in my garden. Dream Weavers somehow hits the right vibe for this task preparing for Spring.

https://m.youtube.com/watch?v=mDZ6B8R4UX4&list=RDmDZ6B8R4UX4&start_radio=1&pp=ygUTc3B5cm8gZHJlYW0gd2VhdmVyc6AHAQ%3D%3D

The Blueprint for Dominating Your Local Market Sector

約10時間 ago • Conventions, Meetups, and Gatherings

約10時間 ago • Conventions, Meetups, and Gatherings

More

約10時間 ago

More

約21時間 ago

Geez... Such bad writing.

You just solo'd a black dragon boss monster that none of could defeat and was about to wipe a few dozen members of our guild. We want you to join us... But first, "Will you sacrifice your life for our guild?"... "No?! How dare you!!! You're not fit to join us!!"

It went from a low-stress, friendly, casual guild. To super intense, swear to sacrifice your life for us... Who writes this crap? That in no way added to or enhanced the story at all. That whole scene was just a huge waste of time that did nothing for the plot and should have been edited out.

Posting Messages For Gabe (@Gabriel_True) Until He Comes Back To The Land Of The Living

約22時間 ago • Random Chatter

約22時間 ago • Random Chatter

More

約22時間 ago

@gabriel_true

Day 125: Dinner was pasta and garlic bread, it was delicious! Especially the bread...I'd eat up a whole bakery if I could lol, my family calls me the bread thief because as soon as that loafy goodness is in our house, it's gone in a second. I promise I am considerate of the rest of my family and wait for them to have their fill before I tear into it!

If we had the money, I'd love a crap ton of bread and a cheese wheel for my Birthday this year XD (I also really love cheese)...I'm a simple woman truly, so don't judge me, our mom already dislikes the fact I ask for necessities as a gifts rather than wants, but it's just the fact that I'm bad at asking for things I want just because I feel like our parents already have given me so much every year. So...when you think about it, it's actually my mom's fault for giving the best gifts to where I'm satisfied and only ask for food/snacks each year lol. But, I can't wait to get to our Birthday (me and baby brother's), cause she is reeeeeeally excited about whatever it is she's got me as gifts this year...which I have a feeling is NOT going to be food lol.

Anyways, the cheese wheel will have to wait for when we can afford it *rubs hands together*, but just you wait until I get my hands on one. Everything I eat will have cheese on it XD. - Imma Go Eat Cookies Now: Cookie Mama

More

Yesterday at 4:55pm

relaxing doom.

https://www.youtube.com/watch?v=KHL_avf3LlI

Yesterday at 3:31pm

My favorite anime of all-time is Re:Zero!

It has the BEST character development that

I've ever seen in any form of media!

More

Yesterday at 3:29pm

I'm currently watching the second season of Frieren: Beyond Journey's End, and it's absolutely beautiful! I'm also going to start watching The Misfit of Demon King Academy soon too!

More

Yesterday at 3:01pm

More

Yesterday at 2:26pm

https://media1.tenor.com/m/C3kT59YcQIkAAAAC/really-seriously.gif

More

Yesterday at 8:15am

I'll be your friend! :)